Customer Q&A - Focusing on Core Concerns

Steel Backing Corrugation Purchasing Guide: An In-Depth Analysis of the Five Most Concerning Questions for Construction Contractors

As a professional manufacturer with many years of experience in the steel backing corrugation industry, we understand the questions you may have when considering this new support material. Below are detailed answers to the five most frequently asked questions by construction contractors to help you make an informed decision:

Question 1: Is steel backing corrugation truly more cost-effective than using wood or traditional steel bracing? At first glance, the price may seem high.

Answer: Yes, the overall cost advantage is significant. While the purchase price per piece may be higher than that of wood or ordinary steel, please consider the following factors:

High-quality hot-dip galvanized steel backing corrugation can be used over 300 times, while wood is typically only used a few to a dozen times. Ordinary steel bracing is also prone to deformation and rust, shortening its lifespan. Amortized over the long term, the per-use cost is extremely low.

Low-Waste Rate: Durable and resistant to damage, deformation, or loss (compared to wood, which is prone to wear and tear).

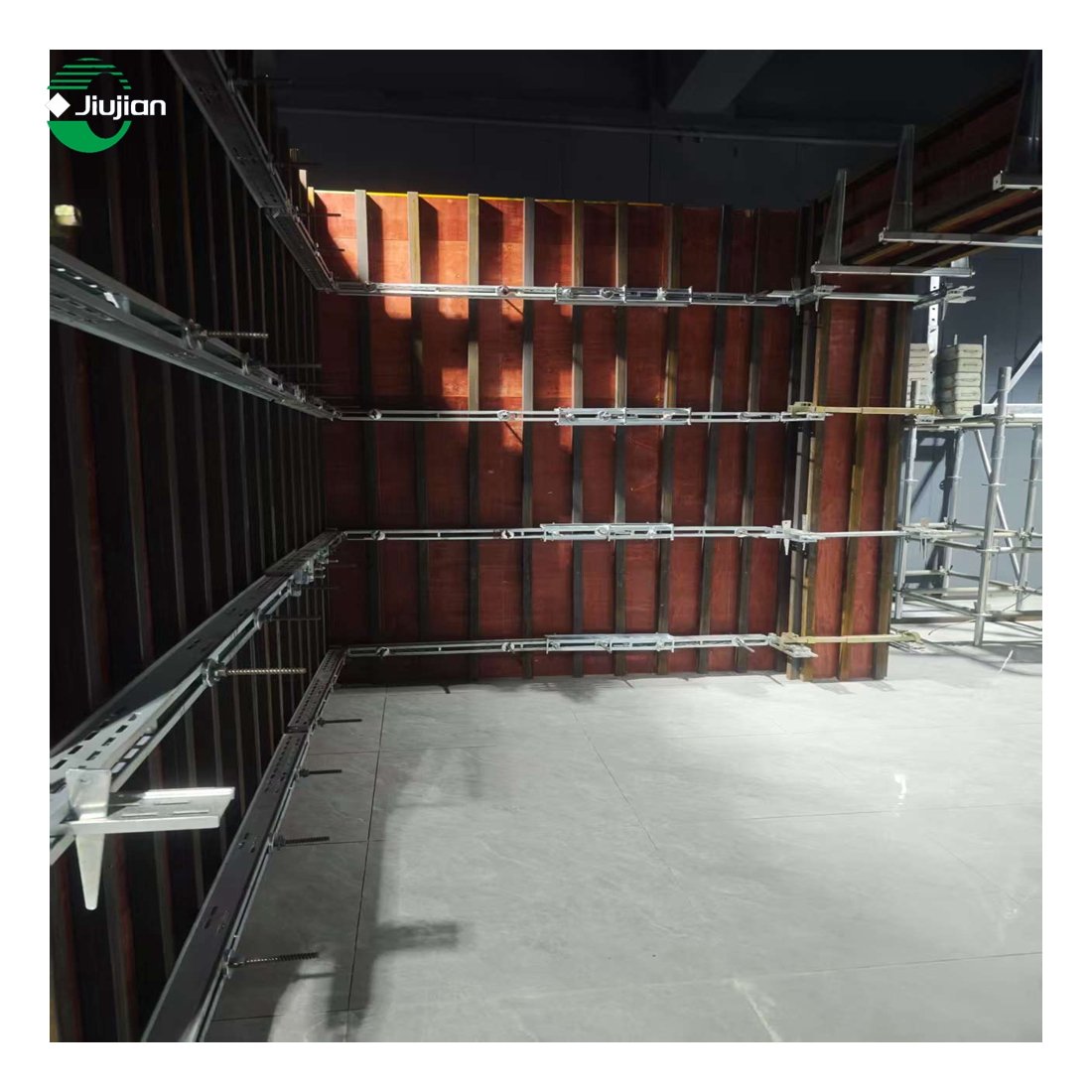

Significant Labor Savings: The lightweight design speeds up handling and installation, saving 15%-30% in labor costs and time.

Excellent Forming Quality: Reduces problems such as concrete formwork explosion, grout leakage, and surface unevenness, significantly reducing the cost and time of subsequent repairs.

Conclusion: From an overall project cost perspective, steel backing can provide significant long-term economic benefits and a positive return on investment.

Question 2: Is the load-bearing capacity of steel backing sufficient? How can I choose the appropriate specifications for my project?

Answer: Absolutely sufficient! Our steel backing is designed for high loads. For example:

The commonly used steel backing with a size of 80mm x 40mm x 2.5mm has a flexural section modulus (Wx) of approximately [please enter a specific value, e.g., 34.5 cm³] and an allowable bending moment of up to [please enter a specific value, e.g., 10.35 kN.m] (based on Q345B material).

When selecting a model, factors such as concrete lateral pressure (affected by pouring height, pouring speed, slump, and vibration method) and support spacing must be comprehensively considered. We provide detailed load calculation reference tables and selection guides. Simply provide your project's basic parameters (such as wall height, wall thickness, and pouring speed), and our technical team will provide you with a professional specification and matching plan free of charge. Our product design complies with major international building codes.

Q3: Is installation and disassembly complicated? Will special tools or training costs be required?

Answer: Installation is extremely easy and efficient!

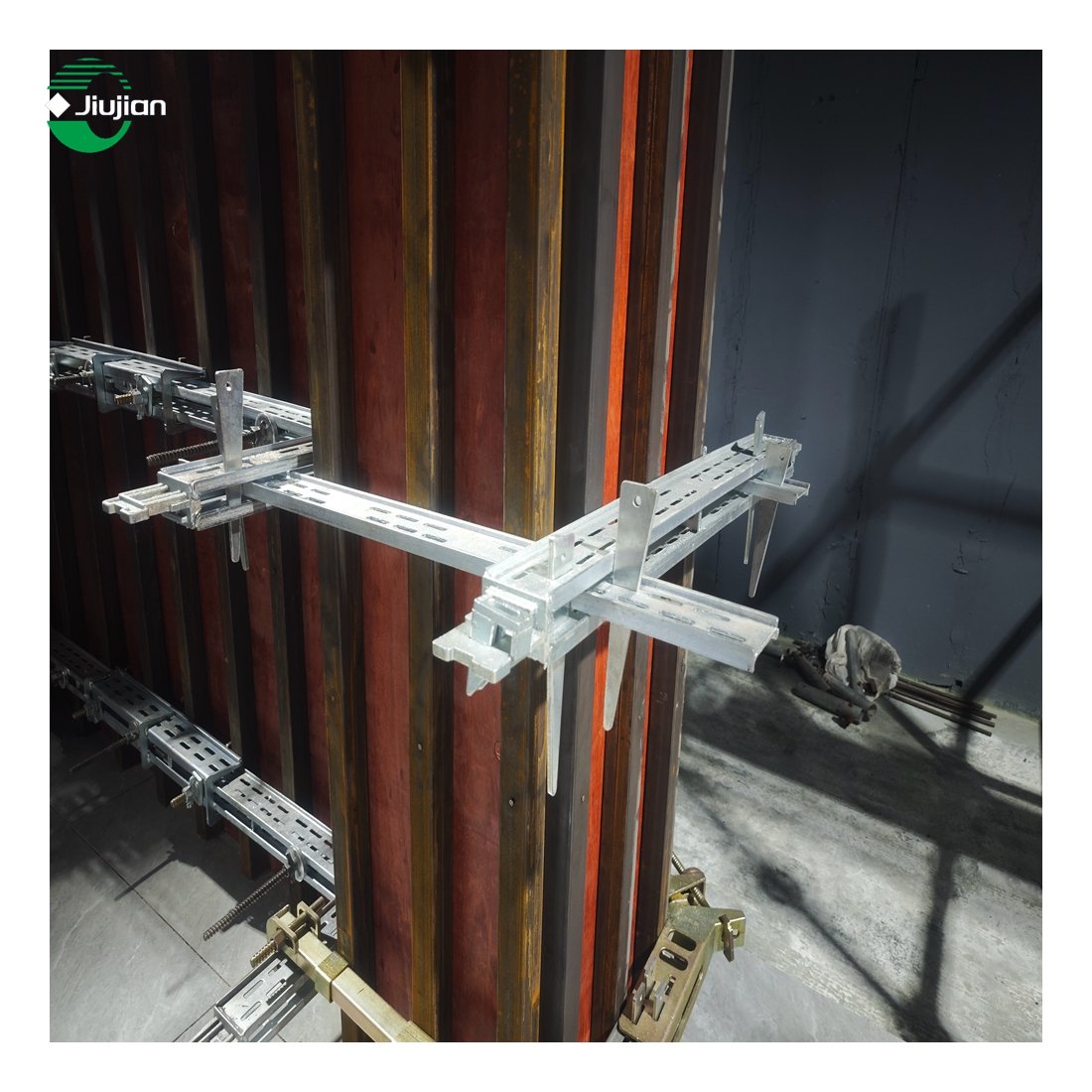

Using standardized components and simple, reliable connection methods (such as quick wedge pins, high-strength bolts, or specialized clamps), installation can typically be completed with just a standard wrench.

The clear structure allows for quick onboard operation, with a short learning curve and no lengthy specialized training required.

The lightweight design makes overhead handling and positioning adjustments easier and safer. Once proficient, installation can be significantly faster than traditional methods.

Q4: What is the corrosion resistance of the steel backing? Can it be used in humid, coastal, or chemical environments?

Answer: Excellent corrosion resistance, suitable for a wide range of environments! The key lies in our hot-dip galvanizing process:

After rigorous pre-treatment, the steel is immersed in high-temperature molten zinc to form a dense, firmly bonded zinc-iron alloy layer. The standard zinc layer thickness is ≥80μm, meeting or exceeding international standards (such as ASTM A123).

It offers excellent weather and corrosion resistance, effectively withstanding rain, humidity, construction site mud, and harsh coastal salt spray environments. It maintains excellent condition even after prolonged use and repeated water washing, ensuring long-term performance and service life.

Question 5: How can I ensure the quality of the steel backing I purchase? How do you conduct quality control?

Answer: Choosing a reputable, professional manufacturer is crucial! We strictly control quality:

Source control: We strictly select high-quality steel that meets standards (material certification is provided) and reject inferior raw materials.

Precision manufacturing: Advanced production lines ensure dimensional accuracy (tolerances within ±0.5mm) and solid, defect-free welds.

Galvanizing Guarantee: We monitor the hot-dip galvanizing process throughout the entire process to ensure uniform, standard-compliant zinc coating thickness and strong adhesion.

Strict Quality Inspection: Each batch of products undergoes multiple inspections before shipment, including visual inspection, dimensional spot checks, and zinc coating thickness testing (using a professional thickness gauge).

Quality Certification: We provide product quality certificates and relevant management system certifications (such as ISO 9001).

Seeing is believing: We encourage customers to visit our factory or request samples for actual testing and verification.

Choosing us means choosing reliability and efficiency!

[Contact our sales engineers now for a customized project proposal and quote] or [Submit your project specifications online for free selection advice]